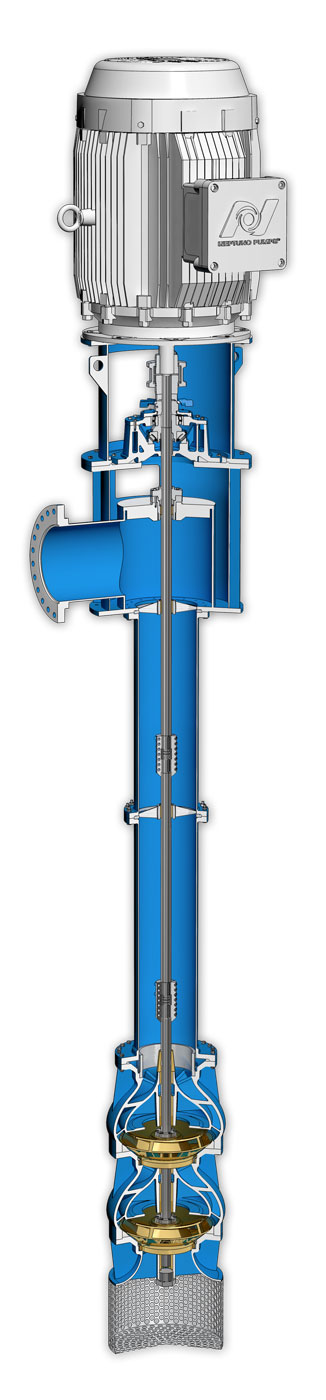

DESIGN FEATURES

? Low NPSH first stage construction

? Thrust balanced impellers available

? Packing or mechanical seal

? Independent axial-thrust bearing assembly

? VS1, VS2, VS3, VS6 & VS7.

MATERIALS

? Bronze, Cast Iron, Carbon Steels

? Stainless Steels – 316, 317 SS

? Duplex – 2205

? Super Duplex – 2507

? Super Austenitic – 254 SMO, 654 SMO

? Nickel-Based Super Alloys – Hastelloy

? I-1, I-2, S-1, S-3, S-4, S-5, S-6, S-8, C-6, A-8 and

D-1.

INDEPENDENT AXIAL THRUST BEARING ASSEMBLY

? Withstands the total hydraulic

thrust as well with the rotor

weight

? Allows servicing with standard

drives

EXTERNAL LUBRICATION SYSTEM

Vertical Turbine Pump – Enclosed Shaft works with its own External Lubrication System for highly corrosive material handling.

OPERATING PARAMETERS

? Capacities up to 25000

(m3/h) (95000 gpm)

? Head up to 600 (m) (1968

Feet)

? Power through 2.237

(kW) (3,000 hp)

? Frequency 50/60 Hz

? Temperatures to 200 (?C)

(400 ?F).